Kicking it off: the search for a property

Vanilla only grows between the 20th parallel North and the 20th parallel South around the globe.

The finickiest of finicky plants, vanilla requires just the right amount of sun, just the right amount of water, just the right humidity and, of course, just the right location on the earth.

The finickiest of finicky plants, vanilla requires just the right amount of sun, just the right amount of water, just the right humidity and, of course, just the right location on the earth.

This limits the habitat for larger-scale vanilla production to: Madagascar, Mexico, Indonesia, Uganda, Papua New Guinea, India, Comoros, Guadeloupe and Martinique, Reunion Island and, of course, Hawaii.

The location of Alaula farms was a difficult search requiring consideration of all the obove factors. The Hilo side tends to get too much rain and cloud cover. The south west tends to get vog which the vanilla can react badly to. As Goldilocks would say, the combination of latitude, sun and humidity makes the northern gold coast "just right."

Pollinating Vanilla - busy as a bee

The Endangered Melipona bee Macrogalea ellioti a stingless bee, evolved in parellel to the vanilla orchid and for most of the world history provided the only mechanism for pollination of the vanilla orchid flower.

The Endangered Melipona bee Macrogalea ellioti a stingless bee, evolved in parellel to the vanilla orchid and for most of the world history provided the only mechanism for pollination of the vanilla orchid flower.

The flower of the vanilla orchid only blooms for a few hours in the early morning once a year. If you're not busy as a bee manually pollinating in that short timeframe, a vanilla bean will not be produced that year. A single vanilla vine may produce several dozen flowers over the season, each on a different day. This means the vanilla farmer needs to very carefully pollinate each flower every day for months at a time. Intensive work indeed.

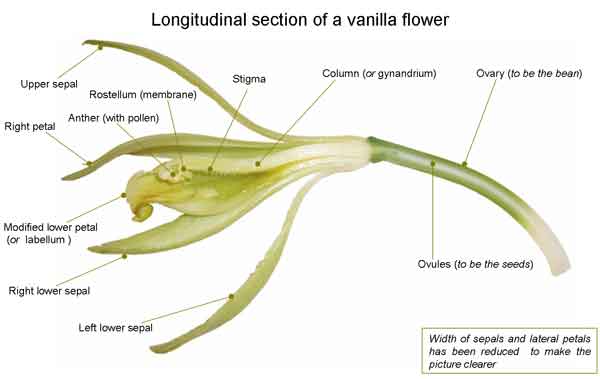

The flower will not self pollinate as the rostellum blocks the stigma, preventing the pollen on the anther from accessing the ovary in the stalk of the flower. To manually pollinate the vanilla, the farmer must carefully open the petals to expose the modified lower petal containing the reproductive parts and then, without dislodging the pollen packet loosely attached to the anther, lift the rostellum up and away, but not removed or torn, so that the pollen can migrate to the ovary.

The rostellum, which in its natural position sits pointed back to the base of the flower, looks similar to a diaphragm window and can range from nearly transparent to transluscent to opaque.

One major stumbling block is the pollen, which is above the rostellum, is very loosely attached to the anther and can be dislodged with something so slight as an errant breath. The pollen, while bright yellow, is still easy to miss as it's only a little larger than a grain of sand. Dislodged pollen can still be placed so that it will pollinate, but the probability of success is diminished.

Within a week, the stem of the flower will either start to turn brown and wither, indicating unsuccessful pollination, or remain green and begin to enlarge into a vanilla bean.

Water Loss Resistant Vanilla trellis design

Soil permeability is a significant factor in cost. Recovering, storing and filtering any runoff is key to a sustainable vanilla farm on the driest of the dry sides.

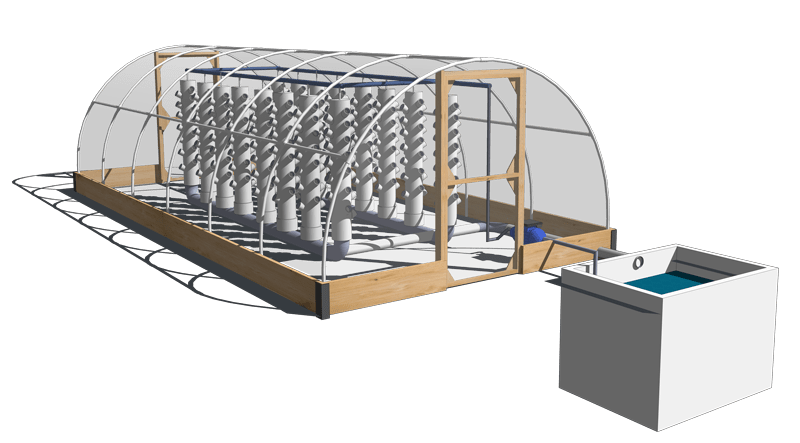

With the minimization of water loss as a primary focus, the trellis design needed to emphasize water retention and recovery. Typically each vanilla stalk will use 10 gallons of water per day with roughly half that running off into the soil. The trellis stalk by Alaula farms is designed to catch that 50% runoff and store it in a clarifying storage tank for separation and filtration.

The recycles and fresh water mix enters through a mister at the top of the trellis and filters down using capillary action down the fibrous interior of the trellis stalk. The vanilla can access the water through coconut husk fibers extending from the column access holes and branching out to the exterior perimeter.

An excess water is captured at the base of the trellis stalk and returned to a sedimentation holding tank. The recycled water is drawn from the middle portion of the sedimentation tank while the salt and undesirable mineral heavy water that settles to the bottom and the algea and foaming upper effluent of the tank is periodically discarded. The water is then exposed to strong UV light for sanitization before returning to the vanilla.

Wind & Water Loss Resistant Greenhouse/Shade-house design

How to minimize evaporation, battle strong winds and provide just the right amount of sunlight? A smart shade house.

Vanilla vines are persnickety. Like goldilocks, they need conditions to be just right: not too much sun, not too little. Not too much water, not too little. Not too much humidity, wind, altitude, the list goes on. To help control all these factors, a shade/green house is a necessity.

The north Kohala sun is strong. Too strong for Vanilla lines if left unprotected. So shade of between 40% and 70% filtration is needed. The type and sunlight filtering ability of the shade cloth needs to be changed throughout the seasons, so the system the shade cloth is attached to needs to allow rapid changing of shade cloth.

The north Kohala wind can get extreme. 38 m.p.h. wind speeds are common in the winter months, 75 m.p.h. wind speeds are not unheard of. this would, at best, knock over any unprotected vanilla, if not dry it out of tear the leafs off the vine. The vines must be protected by a greenhouse, but at the same time, the greenhouse cannot become a solar oven.

Vanilla propagation and cuttings

While it's not impossible to grow vanilla from seeds, to get a better chance of success quicker, vanilla is propagated through cuttings.

Vanilla cuttings can be made in any length longer than 24 inches. However, the longer the vine cutting, the sooner it will flower. For example a 24 inch cutting can be expected to flower in 3 to 4 years, while a 36 inch cutting just 2 to 3 years. Longer cutting reduce the amount of time until flowering further still. A five meter long cutting (196 inches) can be expected to flower as soon as the same season of it's transplanting.

Transplanting is stressfull on all plants. With how melodramatic vanilla vines can be: they don't even like minor changes in humidity, transplanting, or even transporting, can cause crop failure. So you ease the stress, Alaula Farms will be providing the growth stalk to the nursery where our vanilla will be sourced.

From the vanilla vines to the extract base, everything hana ʻia ma Hawaiʻi

At Alaula Farms, we're focused on making everything ourselves with material from the islands. From the coconut husks and macadamia nut shells that make up the bulk of the vanilla trellis, to the ethyl alcohol distilled from local Kiawe beans. All 808.

Sustainability, independence and low carbon footprint are an important focus at Alaula Farms. The waste and pollution of shipping raw materials from elsewhere, then using then for manufacture on island along with the waste created, and then likely flown back to the mainland in tourest luggage is not lost on us.

So a consistant driving goal in Alaula farms is to try hard to source as much locally as possible. Supporting the local economy, reducing the dependance on mainland goods, and reducing unnecessary fuel usage.

Scruffy, tough, and with vicious 3 inch long thorns

The humble Kiawe bean, practically everywhere on the dry side, has a surprisingly high fructose percentage which can be used directly for fermenting and distilling.

Unlike most grains that need to have their long-chain complex carbohydrates broken down to simple sugars in a mash, the Kiawe bean has an already simple sugar, fructose, and in spades. Fructose can be directly fermented using standard brewer's yeast.

The process of extracting the fructose is simple: boil around one pound of good ground Kiawe beans per gallon of water for about 2 hours, strain off the solids and reduce the resulting mixture to a Kiawe mesquite molasses. The molasses can be used to made a moderately high alcohol beer which then can be distilled to ethyl alcohol the make the vanilla extract base.

The Kiawe mesquite molasses also makes for a great BBQ sauce.

The small scale requirements of vanilla extract base, likely no more than 2 or 3 gallons per season, makes it idea to use a column still to distill. Column stills are inexpensive, safe, small batch stills that can refine ethyl alcohol to any proof desired.